Comprehending the Trick Parts and Repair Approaches for Packaging Equipment Maintenance

Effective maintenance of product packaging equipments hinges on a comprehensive understanding of their crucial parts, consisting of the framework, drive system, and sealing devices. Acknowledging typical upkeep concerns, paired with the execution of preventative strategies and troubleshooting methods, can considerably boost device integrity. The choice of repair service techniques, consisting of the use of OEM components and the relevance of licensed professionals, plays a vital function in decreasing downtime. To truly understand the ins and outs of these systems and their upkeep, one must consider the broader implications of disregarding these important techniques.

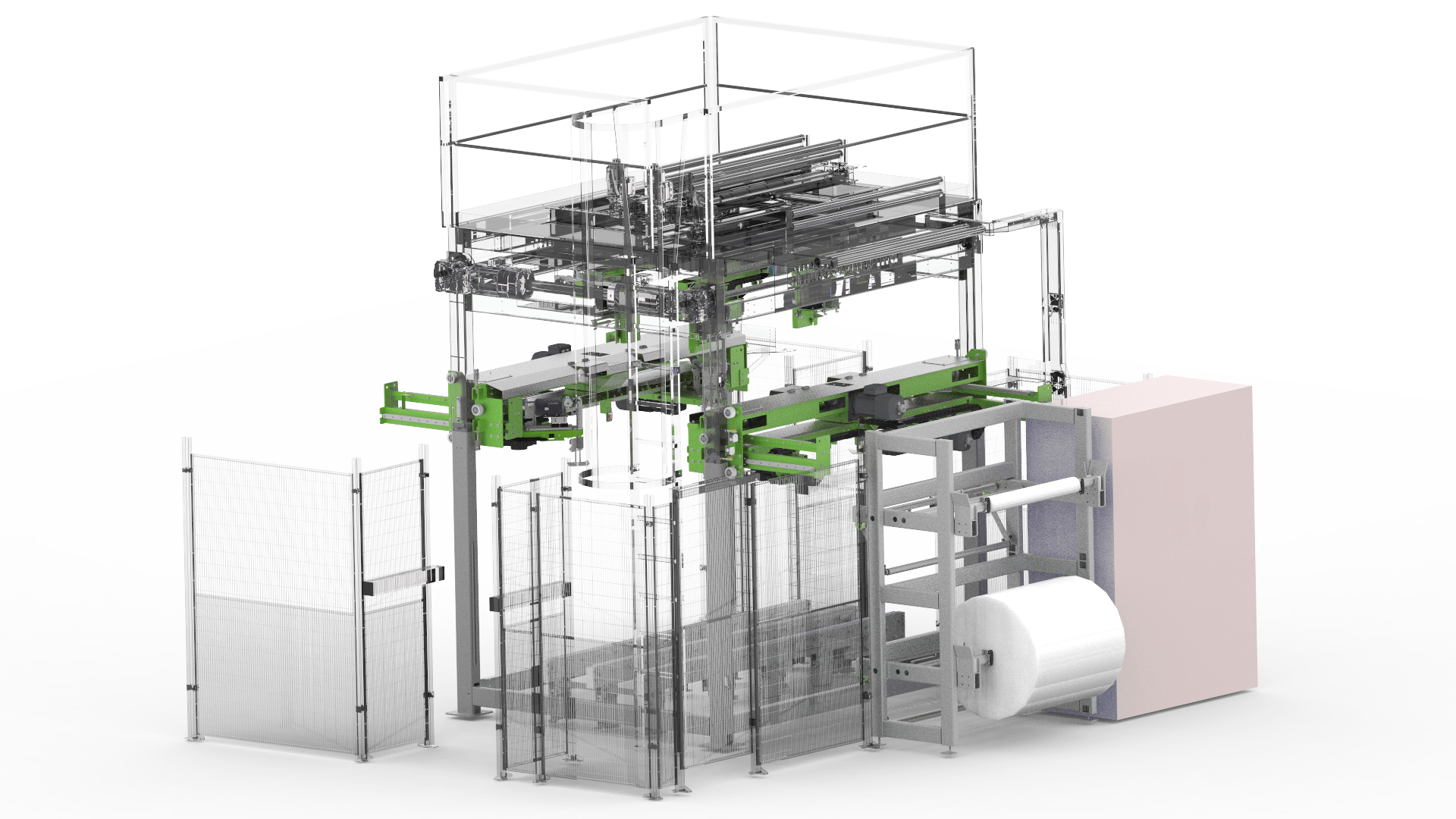

Secret Components of Packaging Machines

Product packaging equipments include a number of crucial elements that interact to make certain reliable and effective product packaging procedures. At the core of these makers is the frame, which supplies architectural stability and houses the numerous operating parts. The drive system, commonly a combination of electric motors and equipments, promotes the movement of parts, allowing exact procedure throughout the product packaging cycle.

Another crucial part is the conveyor system, which delivers products via various stages of the packaging process. This is often enhanced by sensors and controls that monitor the position and rate of things, guaranteeing synchronization and decreasing mistakes. The loading system is essential for properly dispensing the best amount of product into packages, whether in liquid, powder, or strong form.

Sealing systems, consisting of heat sealers or glue applicators, play a vital function in safeguarding plans, avoiding contamination and extending rack life. Additionally, identifying systems are integral for offering required item info, making certain conformity with regulations. Lastly, the control board, furnished with easy to use interfaces, enables drivers to handle machine functions, monitor performance, and make changes as needed, guaranteeing ideal efficiency and effectiveness in packaging procedures.

Typical Upkeep Concerns

Efficient operation of packaging machines relies heavily on normal upkeep to stop typical problems that can disrupt production. Among these issues, mechanical damage is prevalent, specifically in components like conveyors, electric motors, and seals, which can bring about unanticipated downtimes. Furthermore, imbalance of parts can result in inefficient operation, creating items to be incorrectly packaged or damaged during the procedure.

Another typical maintenance problem includes the accumulation of dust and particles, which can disrupt the machine's sensors and relocating parts. packaging machine repair service. This not just influences performance yet can also present security dangers. Lubrication failures can lead to enhanced rubbing, resulting in overheating and eventual element failing.

Electric problems, usually coming from loose links or worn-out circuitry, can disrupt equipment features, bring about significant manufacturing hold-ups. Finally, software application glitches because of obsolete programs or inappropriate setups can impede the equipment's operation, requiring instant intervention. Addressing these usual maintenance problems proactively is crucial for making certain optimum performance and long life of product packaging equipment.

Preventative Upkeep Techniques

Implementing preventative upkeep techniques is critical for sustaining the performance and integrity of product packaging machines. These techniques incorporate a systematic approach to upkeep, concentrating on the routine inspection and servicing of tools to preempt potential failures. By adhering to a set up maintenance program, operators can determine wear and tear on elements prior to they cause substantial failures.

Trick elements of a preventative maintenance method include regular examinations, cleansing, element, and lubrication substitutes based upon manufacturer referrals. Using lists can enhance this procedure, guaranteeing that no vital jobs her explanation are overlooked. Additionally, preserving exact documents of upkeep activities aids in tracking the machine's efficiency gradually, assisting in informed decision-making relating to future maintenance needs.

Training team on the relevance of preventative upkeep enhances conformity and fosters a culture of positive treatment. Implementing a predictive maintenance element, making use of information analytics and sensor technology, can additionally enhance equipment performance by predicting failures prior to they take place.

Fixing Methods

When faced with breakdowns or ineffectiveness in product packaging machines, using methodical troubleshooting techniques is important for determining and fixing problems promptly. The initial step in reliable troubleshooting is to establish a clear understanding of the maker's operational criteria and efficiency metrics. This includes assessing the machine's specifications, along with any mistake codes or alerts presented.

Next, operators must carry out a visual evaluation, looking for obvious indications of wear, damages, or misalignment. This commonly consists of taking a look at sensing units, gears, and belts to pinpoint possible sources of breakdown. Collecting operational data, such as production rates and downtime logs, can also offer insights right into reoccuring issues.

Once potential troubles are identified, making use of a rational approach to separate the origin cause is vital. This may need screening specific elements or systems in a controlled fashion. Participating in conversations with operators who interact with the machinery regularly can generate important comments about his concerning unusual behaviors or patterns.

Repair Work and Substitute Best Practices

A detailed understanding of repair work and replacement ideal techniques is vital for keeping the longevity and efficiency of product packaging equipments. Frequently assessing the condition of equipment components enables prompt treatment, stopping even more substantial concerns that can lead to expensive downtimes.

When repair work are needed, it is necessary to make use of OEM (Original Equipment Producer) components to ensure compatibility and efficiency. This not just maintains the stability of the machine however likewise upholds warranty agreements. In addition, it is advisable to preserve a stock of vital spare components to promote fast replacements and reduce operational disruptions.

For intricate repair work, engaging licensed specialists with specialized training in packaging machinery is advised. They possess the expertise to diagnose problems accurately Read More Here and implement repairs efficiently. Furthermore, documenting all repair tasks and parts replacements is essential for maintaining a thorough maintenance history, which can aid in future troubleshooting.

Lastly, implementing a positive technique, consisting of regular inspections and predictive upkeep strategies, improves the dependability of packaging makers. By adhering to these ideal practices, organizations can guarantee optimal maker efficiency, lower operational dangers, and expand tools lifespan.

Verdict

In final thought, a thorough understanding of product packaging device components and effective maintenance techniques is vital for optimal performance. By carrying out these practices, organizations can make sure the longevity and efficiency of packaging machines, inevitably adding to improved functional efficiency and lowered expenses (packaging machine repair service).

Reliable maintenance of packaging makers hinges on a comprehensive understanding of their crucial parts, including the frame, drive system, and sealing devices.Effective operation of packaging machines counts heavily on routine maintenance to avoid typical problems that can interfere with production.Carrying out preventative maintenance approaches is critical for maintaining the effectiveness and dependability of packaging makers. Furthermore, maintaining exact documents of maintenance tasks aids in tracking the device's performance over time, assisting in notified decision-making pertaining to future maintenance demands.